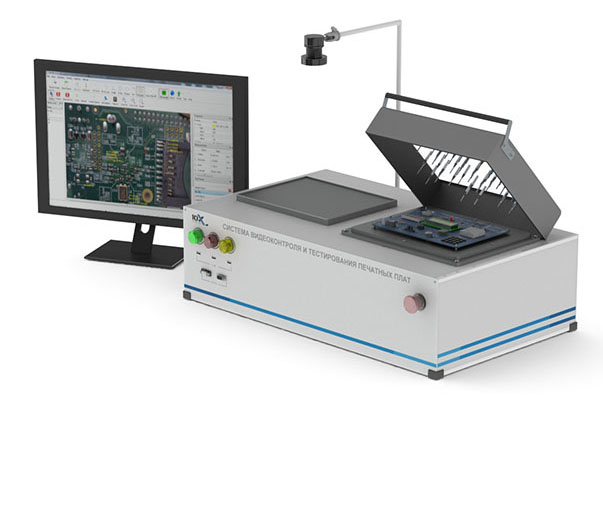

PCB inspection and test low cost system is an essential element in any electronics manufacturing process. The system enables faults detection in PCB masking, soldering, assembling and other phases, whether for large scale /high volume or low volume manufacturing.

Current system allow simultaneously with optical inspection, measure electrical parameters, using system’s fully programmable Digital-Analog Input\Outputs. This functionally make’s the system as a unique functional tool in production, even for high level of complexity boards inspection and testing.

Flexible software and hardware allow system to be used as Automated Test System for PCB testing, where optical and electrical measurements can be combined.

Functionality :

- Automated failure detection

- High quality\resolution digital picture 1600×1200 (2.0 M pixel)

- High working distance

- High Field of View (FOV)

- Light illumination auto\manual control

- Analog Input – 2Ch. 500MS\s 8bit ±25V, bandwidth 100MHz

- Functional Generator -1 ch, 14bit up to 20MHz (sine, square, ramp, DC, etc.)

- Arbitrary Waveform Generator(AWG) – 14bit 125MS\s

- Digital Input\Outputs – 8 Ch. 3,3В CMOS

- Internal power Supply – up to 200V 2A

- Digital Multimeter- resolution 5 ½

Details :

- Author : yeatAdmin

- Category : Production Board Test Systems

- Date : April 19, 2015

Русский

Русский